SBT Consult ApS

YOU NAME IT WE COOL IT.

We have 40 years’ experience worldwide in industrial project.

Dairies, all kind of dairy product: Ice bank – ice water chiller – glycol chiller

SBT CONSULT

Experience

For over 40 years, I’ve traveled worldwide, starting up a wide range of refrigeration systems. My extensive experience covers everything from installation and commissioning to troubleshooting complex issues.

Over the past 10 years, I’ve built my own company and achieved considerable success, primarily with clients in African countries.

Currently, we have a team of four, and for larger projects, we outsource additional tasks.

When it comes to refrigeration products, I only work with the highest quality to ensure long-lasting, trouble-free systems. With my years of experience, I can confidently recommend the right setup for each project. I often see installations today that could have been done more effectively.

Efficiency

Streamlining processes from planning to delivery for timely and cost-effective project execution.

Reliability

Providing consistent, long-term support and high-quality solutions tailored to client needs.

Expertise

Leveraging specialized knowledge and experience to deliver optimal results in every project.

We offer

SBT CONSULT

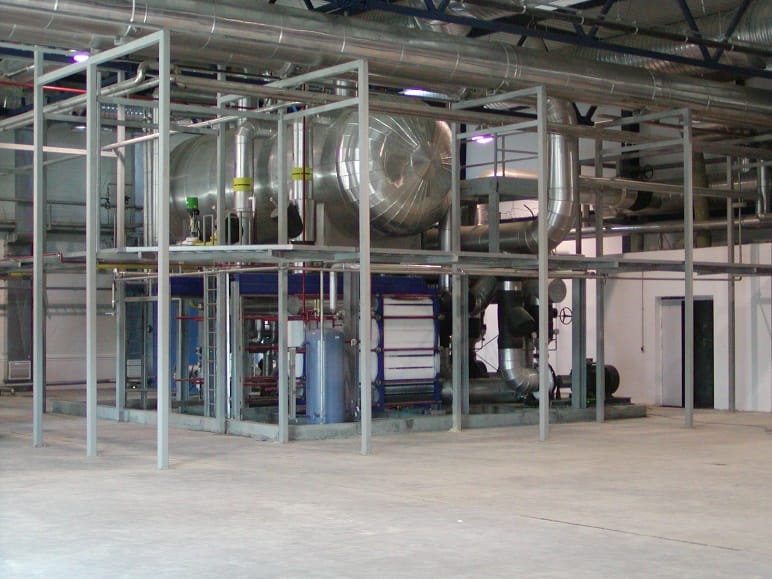

Pac Chillers

We also offer custom-built chillers, where our engineers select components, ship all parts, and handle on-site installation. While assembly takes longer on-site, these chillers are more service-friendly due to their spacious design. In most cases, I recommend this option as it’s more economical, faster to implement, and tailored to specific needs, especially given the current lead time for chillers, which is around 24 weeks.

Our chillers are commonly used in dairies and breweries, where efficient cooling is needed across workspaces. Direct ammonia cooling is not ideal here, as ammonia leaks can occur, causing unpleasant odors that disrupt workers. For these applications, we typically use glycol for circulation.

Standard glycol temperatures range from -6°C to -14°C, though we can adjust down to -35°C if needed. Contact us to learn more.